How to Specify an Inductive Proximity Sensor

Published by Pacific Automation on 30th Mar 2022

Choosing a new or replacement inductive sensor can be tricky—mainly due to the sheer number of options available. Specify your next sensor correctly with this quick overview.

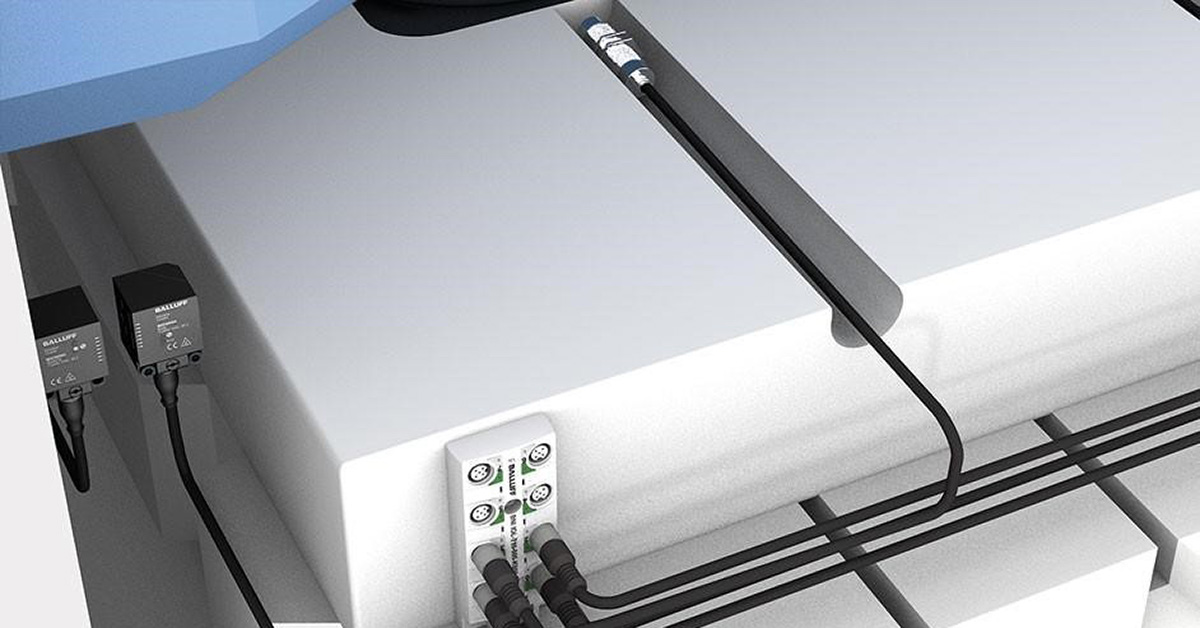

Inductive proximity sensors are common throughout industrial processes.

They’re inherently wear-resistant and reliable solutions for the non-contact position detection of metallic objects.

We supply inductive sensors from Balluff. Their product range alone includes over 2000 variants!

Unless you're a pure sensor specialist, this choice overload can be daunting.

But you're in luck.

This is where our technical sales team comes in. They’re here to help you out!

We’ve also got a Inductive Sensor Selection Guide PDF available for free download.

In this post, we focus on how to correctly specify inductive sensors.

Application-specific options

First things first. Any time we help specify a sensor, our first step is to learn your application.

We’ll ask about any specific requirements & environmental conditions.

Is the sensor being specified for:

-

High temperature environments?

-

High pressure applications, such as hydraulic cylinders?

-

Detection of objects at high speeds up to 20 m/s?

-

Welding applications, such as a robotic weld cell?

-

Non-ferrous metal detection, such as aluminium or brass?

-

Use in food & beverage, or pharmaceutical industries?

-

Hazardous area applications in potentially explosive environments?

There are specific sensor ranges available for each of these applications.

As an example, take hygienic sensors, designed for use in the food & beverage or pharmaceutical industries.

These are built to withstand rigorous cleaning procedures and CIP washdown.

With a smooth body, there's nowhere for dirt or bacteria to collect. High grades of stainless steel are used for ultimate corrosion resistance.

Body Shape & Sensor Size

The next thing to consider is the physical shape & size of your sensor.

Inductive sensors typically come in barrel or cubic housings.

For the more common barrel style sensors, standard sizes range from M5 to M30.

For cubic or block style sensors, standard sizes range from 5mm to 110mm.

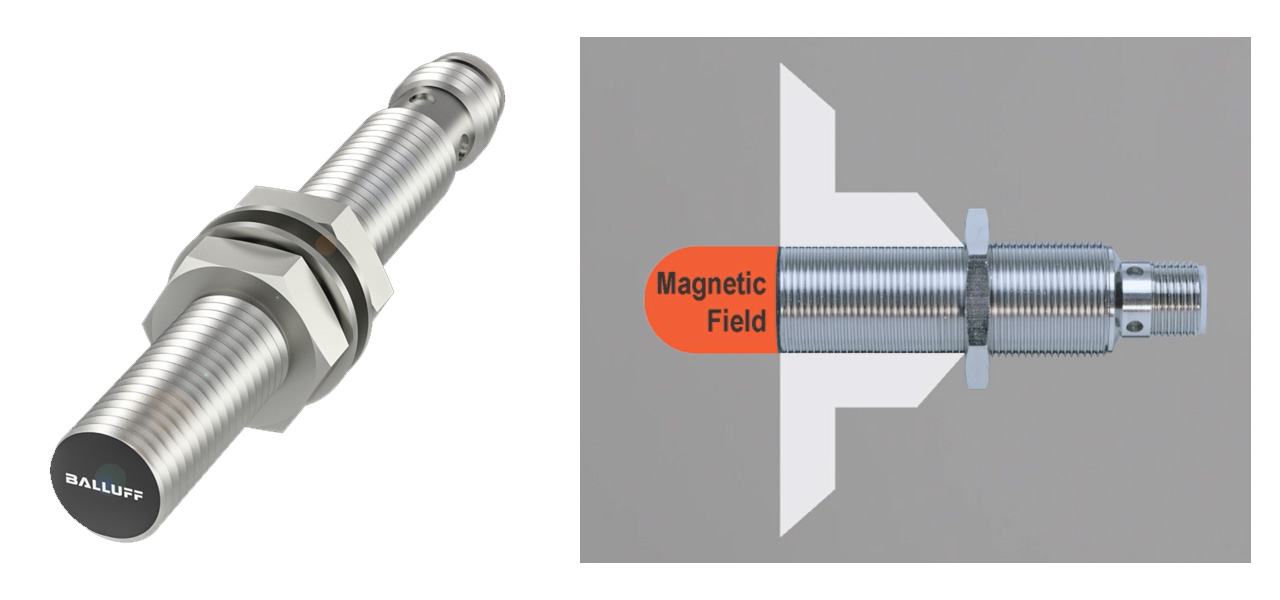

With inductive sensors, the physical size of the sensor correlates with the sensing distance it can achieve.

Larger sensors can generate a larger magnetic field, so they can be positioned at longer distances from the process, while still effectively triggering.

You should already have a fairly good idea of the distance your sensor will be expected to operate at.

Next, assess how much space you have for mounting the sensor around your target process.

This'll help you select the most suitable sensor body shape and size.

Flush & non-flush mounting options

Next, consider how you're going to mount the sensor.

The first option is to install the sensor flush with the material, or bracket.

Flush mounting sensors protects the sensor from accidental mechanical damage.

There's nothing protruding out into the process.

If you need a longer sensing distance, you may benefit from a non-flush sensor and installation.

This means installing the sensor so the face of the sensor protrudes outwards from the mounting material.

The advantage of a non-flush sensor is that you can get an extended sensing range with the same body size.

Flush & non-flush sensors are also commonly referred to as shielded & unshielded, or embedded & non-embedded.

|

Flush |

Shielded |

Embedded |

|

Non-flush |

Unshielded |

Non-embedded |

Electrical output: PNP vs NPN

The next important step is to consider how your sensor should communicate with your control system.

What kind of signal does your PLC expect to receive?

The main options here are PNP, NPN, or 2-wire output.

When it comes to PNP and NPN, you can think of the “P” as standing for “Positive” and the “N” as standing for “Negative”.

Essentially, a PNP sensor will send a positive signal. An NPN sensor will send a negative signal.

The majority of inductive sensors are PNP. However, if you require it, we do supply full ranges of NPN and 2-wire output sensors as well.

Connector vs Cable

Next, decide on the most suitable physical connection.

The options here are either a connector, where you’ll plug a separate cable in, or to use a sensor with an integrated cable.

We usually recommend using sensors with in-built connectors whenever possible.

Having a connector on the sensor, rather than an integrated cable, makes future maintenance a simple task.

Sensor connectors are typically M12 or M8.

For applications where a sensor with an integrated cable is more suitable, we've got a range of cable jacket materials available.

Different jacketing materials will offer differing levels of flexibility, abrasion resistance, can be highly resistant to washdown and cleaning chemicals, or can even inhibit the build-up of weld splatter.

We can help you choose the most appropriate jacketing.

Next Steps

Sensors, even those operating in harsh industrial environments, shouldn’t experience constant failure.

With zero moving parts, inductive sensors are inherently reliable and wear-resistant.

If you have an inductive sensor experiencing repeated failure, there’s a good chance that’s due to a less-than-optimum sensor having been specified.

Sensors shouldn’t be viewed as just another consumable.

Companies shouldn’t get conditioned to constant downtime and lost productivity.

The next time you’re specifying sensors, consider your application, your environment, and refer to these key areas to help you find the best solution for the task.

The next time you need a hand selecting a sensor, get in touch with our team. We’re happy to help.

Get more info here, or browse our product range & shop online for inductive sensors today.

You can now sign up to our mailing list to get these updates direct to your inbox.