Headlines

- Enhancing Operational Efficiency with Danfoss IP66 Drives

- Pacific Automation and Microsonic Partnership Transforms Industrial Automation in Australia

- Raytec Lighting Achieves Certification from Australasian Dark Sky Alliance (ADSA)

- Deciphering the Age of a Danfoss VLT Drive: An Essential Guide

- Discover Pacific Automation at Australia's Premier Industry Expos 2024

Product Focus: Ex Lighting Maintenance – Modular Versus Sealed for Life, Part 2

Tuesday, 21 May 2019

We’re continuing with some snippets from our manufacturing partner Raytec’s four-part blog series about ‘modular’ and ‘sealed for life’ LED Ex luminaires, and how the design and certification of these different approaches impacts maintenance.

We’re continuing with some snippets from our manufacturing partner Raytec’s four-part blog series about ‘modular’ and ‘sealed for life’ LED Ex luminaires, and how the design and certification of these different approaches impacts maintenance.

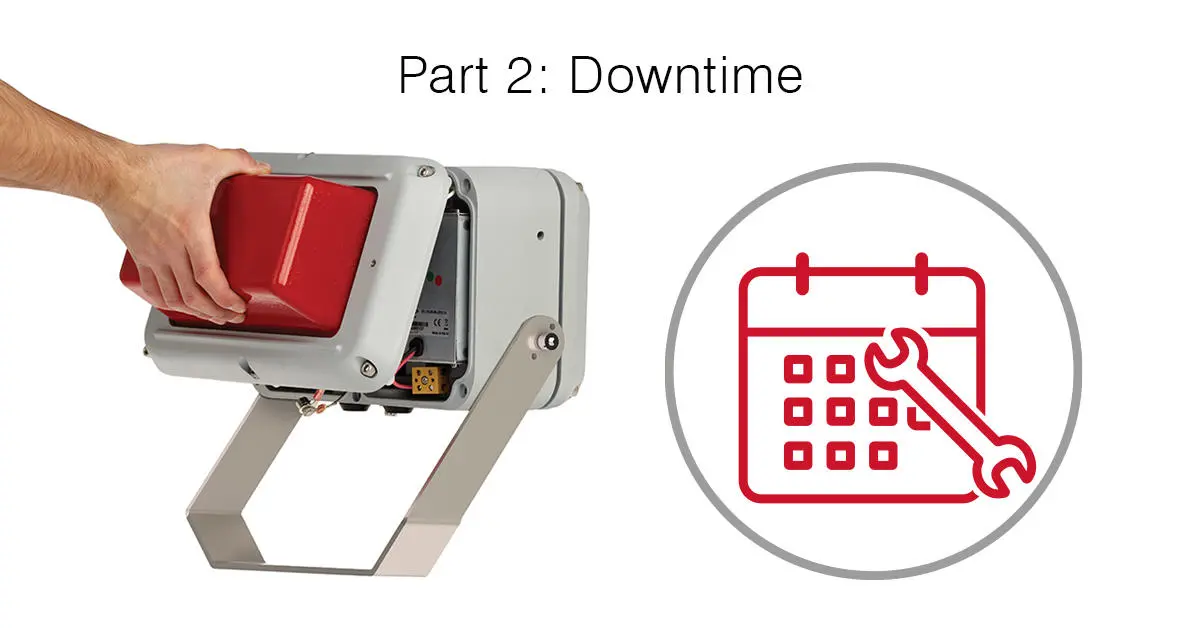

Using a real scenario, the second part looks at how the design affects downtime during a standard maintenance procedure.

If you missed Part 1 – Modular vs. Sealed for Life – What’s the Difference?

Scenario: offshore oil rig

A luminaire installed on an offshore oil rig has failed and the suspected cause is the luminaire’s PSU/driver. A PSU failure will cause either a partial or total loss of light, which may increase risk to workers on the rig and/or require operations to cease. Therefore, resolving this as quickly as possibly is critical.

Sealed for Life Luminaire

If the luminaire is sealed there is nothing the rig’s engineers can do to rectify the problem; doing so would invalidate the certification. The luminaire must therefore be returned to the manufacturer. This takes time and is environmentally irresponsible. The luminaire must be removed, the relevant paperwork raised, and arrangements made to get the luminaire back to shore and to the manufacturer.

At best, the manufacturer will be proactive in replacing the luminaire, but the affected area of the rig will still be left without a light until the replacement arrives. At worst, the manufacturer will ask for the luminaire to be returned and inspected before any corrective action is taken, meaning the rig will be left without light for longer.

Either way, a significant period is likely to pass until light can be restored.

Modular Luminaire

As modular Ex lighting allows access to internal components it can be serviced on-site by the rig’s engineers. Also, because modular Ex luminaire components are interchangeable, spare parts can be kept on site to service the unit. This enables the rig’s engineers to change the PSU/driver in minutes – light can be restored quickly with minimum disruption to operations.

The video below shows how quickly a PSU/driver can be changed on a SPARTAN Zone 1 Linear (the process is similar for replacing a PSU on a floodlight, bulkhead or bay luminaire).

Given a sealed for life luminaire must be returned to the manufacturer, part 3 looks at how this and other features of a luminaire, can impact the environment.

Pacific Automation is the Australian distributor for Raytec’s Spartan and White-Light range of LED lighting products.

Raytec’s Spartan Range of IECEx-certified fittings includes flood, bulkhead and strip lighting solutions.

For more information about Raytec products, email sales@pacificautomation.com.au. As with all Pacific Automation products, you’ll receive technical support and application advice.

This article has been adapted from Raytec’s blog, Maintaining Ex Lighting: Modular vs Sealed for Life – Part 1.

If you missed Part 1 – Modular vs. Sealed for Life – What’s the Difference?

Scenario: offshore oil rig

A luminaire installed on an offshore oil rig has failed and the suspected cause is the luminaire’s PSU/driver. A PSU failure will cause either a partial or total loss of light, which may increase risk to workers on the rig and/or require operations to cease. Therefore, resolving this as quickly as possibly is critical.

Sealed for Life Luminaire

If the luminaire is sealed there is nothing the rig’s engineers can do to rectify the problem; doing so would invalidate the certification. The luminaire must therefore be returned to the manufacturer. This takes time and is environmentally irresponsible. The luminaire must be removed, the relevant paperwork raised, and arrangements made to get the luminaire back to shore and to the manufacturer.

At best, the manufacturer will be proactive in replacing the luminaire, but the affected area of the rig will still be left without a light until the replacement arrives. At worst, the manufacturer will ask for the luminaire to be returned and inspected before any corrective action is taken, meaning the rig will be left without light for longer.

Either way, a significant period is likely to pass until light can be restored.

Modular Luminaire

As modular Ex lighting allows access to internal components it can be serviced on-site by the rig’s engineers. Also, because modular Ex luminaire components are interchangeable, spare parts can be kept on site to service the unit. This enables the rig’s engineers to change the PSU/driver in minutes – light can be restored quickly with minimum disruption to operations.

The video below shows how quickly a PSU/driver can be changed on a SPARTAN Zone 1 Linear (the process is similar for replacing a PSU on a floodlight, bulkhead or bay luminaire).

Given a sealed for life luminaire must be returned to the manufacturer, part 3 looks at how this and other features of a luminaire, can impact the environment.

Pacific Automation is the Australian distributor for Raytec’s Spartan and White-Light range of LED lighting products.

Raytec’s Spartan Range of IECEx-certified fittings includes flood, bulkhead and strip lighting solutions.

For more information about Raytec products, email sales@pacificautomation.com.au. As with all Pacific Automation products, you’ll receive technical support and application advice.

This article has been adapted from Raytec’s blog, Maintaining Ex Lighting: Modular vs Sealed for Life – Part 1.