Product Focus: Ex Lighting Maintenance – Modular vs Sealed for Life

Published by Pacific Automation on 29th Apr 2019

Today we share some insights from our global manufacturing partner Raytec’s four-part blog series about Ex lighting.“Part 1 – What’s the Difference?” compares Raytec’s ‘modular’ and ‘sealed for life’ LED Ex luminaires, and how their design and certification impacts maintenance.

Today we share some insights from our global manufacturing partner Raytec’s four-part blog series about Ex lighting.“Part 1 – What’s the Difference?” compares Raytec’s ‘modular’ and ‘sealed for life’ LED Ex luminaires, and how their design and certification impacts maintenance.Why maintenance is important

Maintenance is required to ensure luminaires are compliant and operating at their optimum. However, carrying out the maintenance can be challenging and costly (both from a monetary and environmental perspective).

Choosing an LED solution will help minimise maintenance, but, given the challenging nature of hazardous area applications, routine maintenance checks are essential, but, as with any electrical product, unplanned maintenance is still a possibility.

Therefore, ensuring maintenance of the luminaire can be carried out as quickly and easily as possible is an important consideration.

So what’s the difference between ‘sealed for life’ and ‘modular’ luminaires in terms?

‘Sealed for life’ luminaires

Many Ex lighting solutions are factory sealed (or encapsulated), primarily for protection (and to meet hazardous area certification). Once sealed, the luminaire cannot be opened and internal components cannot be accessed, ie they’re ‘sealed for life’.

From a certification perspective, this design is generally perceived as being a more straightforward method of achieving Ex approval but does have its limitations. Because the factory seal is such a critical part of the luminaires hazardous area rating, it cannot be opened without invalidating the certification. Doing so would render the unit unsuitable for use in hazardous areas and could present an explosion risk. Therefore, maintenance of a ‘sealed for life’ luminaires is limited.

Modular luminaires

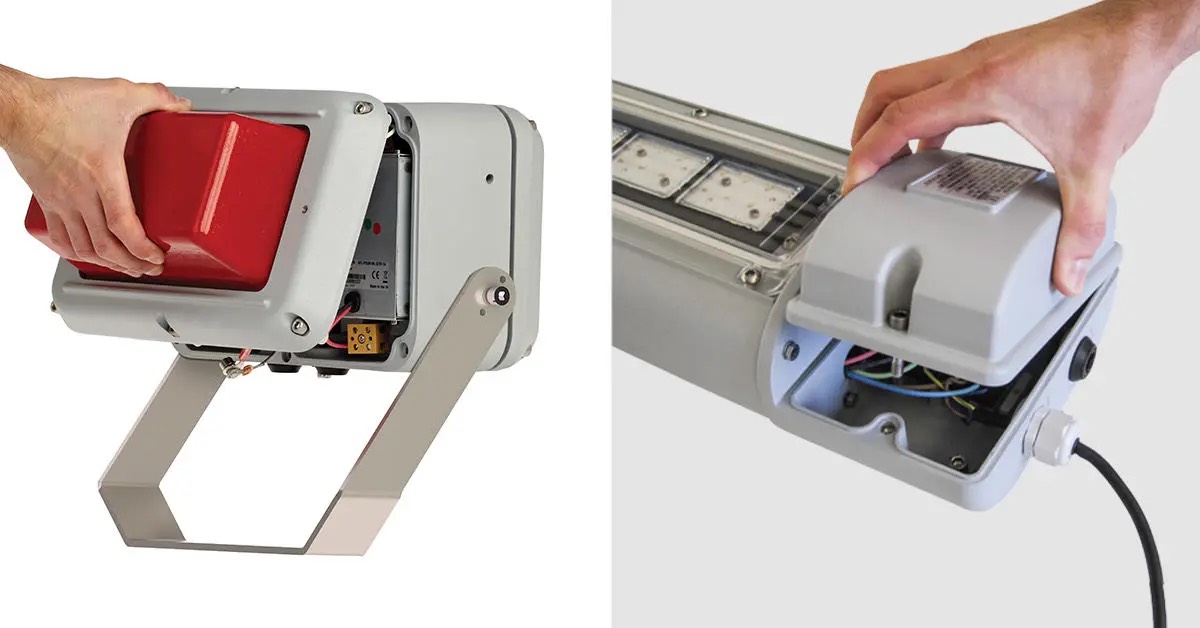

In contrast, ‘modular’ luminaires are designed to allow them to be opened and accessed for maintenance, without invalidating certification. This is mainly because the luminaire does not rely on being factory sealed to achieve its hazardous area rating.

While encapsulation may still form a part of the certification, this is likely to be at a component level (such as encapsulated drivers), rather than the entire luminaire. Without this restriction, maintenance becomes much easier and components can be changed or inspected without invalidating the luminaire’s certification.

So that’s the difference. Part 2 will explore downtime during maintenance, and how the design of these two solutions affect the length of time a user is likely to be left without light during a common maintenance procedure.

Pacific Automation is the Australian distributor for Raytec’s Spartan and White-Light range of LED hazardous area lighting products. Raytec’s Spartan Range of IECEx-certified fittings includes flood, bulkhead and strip lighting solutions.

For more information about Raytec products, email sales@pacificautomation.com.au. As with all Pacific Automation products, you’ll receive technical support and application advice.

This article has been adapted from Raytec’s blog, Maintaining Ex Lighting: Modular vs Sealed for Life – Part 1.