Still Running Fluro Lighting? Here’s Why the World Is Moving On

Published by Pacific Automation on 4th Dec 2025

For decades, T5 and T8 fluorescent tubes have been the workhorses of industrial lighting. They’ve lit our walkways, processing areas, switch rooms, and plant infrastructure reliably enough, until they didn’t. Anyone responsible for site maintenance knows the story all too well: constant failures, flicker in extreme weather, and the ongoing challenge of replacing tubes in hard-to-reach places.

But globally, the world is shifting, and fast. And if your site is still dependent on traditional fluorescent lighting, now is the time to understand why upgrading is no longer just a performance decision, but a risk-avoidance one.

Fluro Tubes Are Already Being Phased Out Globally, and Australia Is Next

In the UK and Europe, the production and sale of most T5 and T8 fluorescent tubes for general lighting is now banned. While Australia has not imposed identical restrictions yet, the transition is well underway due to our obligations under the Minamata Convention on Mercury. This international agreement requires all member countries, including Australia, to phase out mercury-added lighting products in favour of safer alternatives.

As a result, Australia has already begun implementing mercury-based lighting bans, with more scheduled over the coming years. Even before these deadlines arrive, the industry is already feeling the impact:

- Supply is tightening

- Prices are rising

- Ballasts and tubes are harder to source

- Manufacturers are discontinuing production

If your site relies on fluorescent lighting, these disruptions will only increase as the phase-out deadlines approach.

When Will Fluorescent Lighting Be Phased Out in Australia

Australia is progressively banning the import, export, and manufacture of mercury-containing lamps. For industrial users, these key dates matter most:

Already Banned (since 7 March 2022)

Australia has already prohibited several categories of fluorescent lamps, including many with mercury levels above specified limits.

31 December 2026 – Halophosphate Linear Fluorescent Lamps (LFLs) Banned

This includes many older-style T8 lamps used across industrial sites.

31 December 2027 – All Remaining Linear Fluorescent Lamps Banned

This covers:

- Modern T5 and T8 triband phosphor tubes

- U-bend and circular fluorescent lamps

- Any general lighting LFLs not previously banned

In practical terms, new T5 and T8 tubes for general lighting will no longer be able to be imported or manufactured in Australia after 31 December 2027. Existing stock manufactured or imported before the deadline can still be sold and used until it runs out.

The Maintenance Headache You Know Too Well

These regulatory changes simply accelerate a problem that maintenance teams have dealt with for years:

- Frequent tube failures

- Inconsistent performance in extreme heat or cold

- Hard-to-reach fittings requiring lifts, paperwork and downtime

Every failed tube adds labour, cost, and risk, not just inconvenience. With the fluorescent phase-out underway, maintaining these fittings will become increasingly expensive and unreliable.

Fortunately, there’s now a far better option.

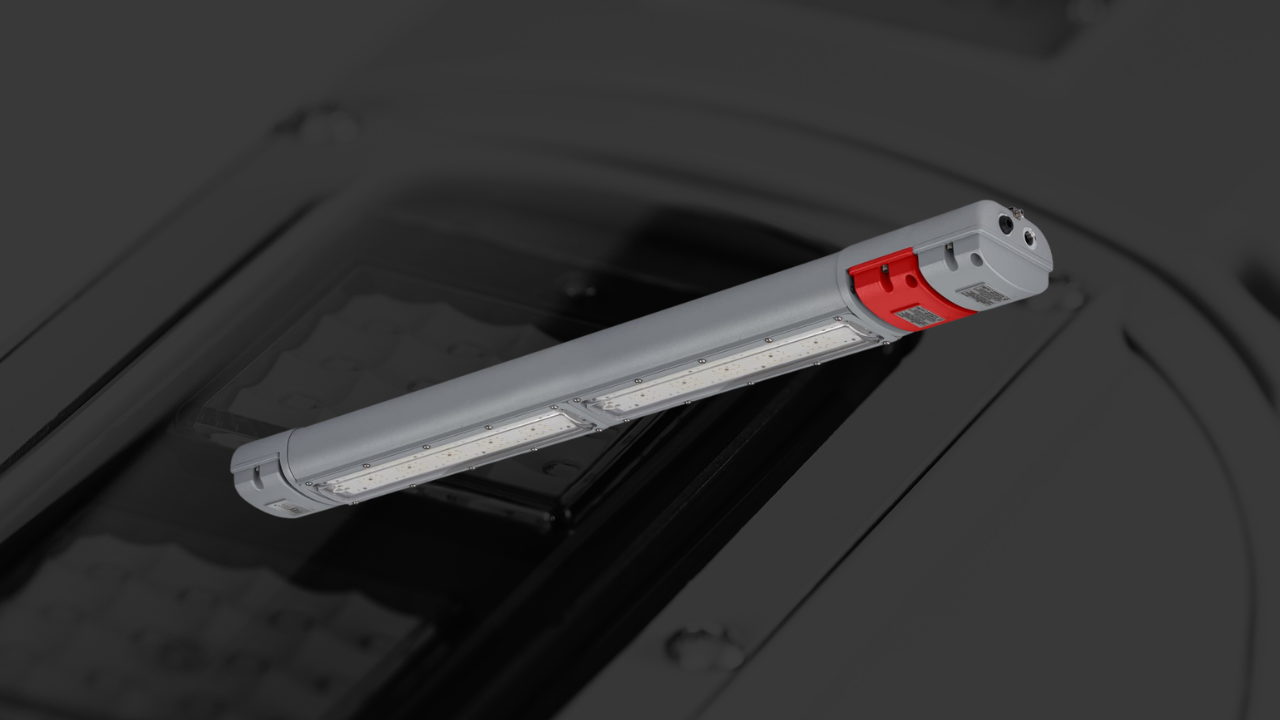

Introducing Raytec SPARTAN LED Built for Industrial Sites

SPARTAN LED luminaires are not just LED replacements, they're engineered specifically for harsh industrial environments. SPARTAN delivers:

- Zero relamping

- 100,000+ hour lifespan

- Reliable performance in heat, cold and vibration

- Retrofit-ready installation

This means fewer shutdowns, fewer call-outs, fewer safety exposures, and far lower life-cycle costs.

More Power. More Value. Fewer Fittings Needed.

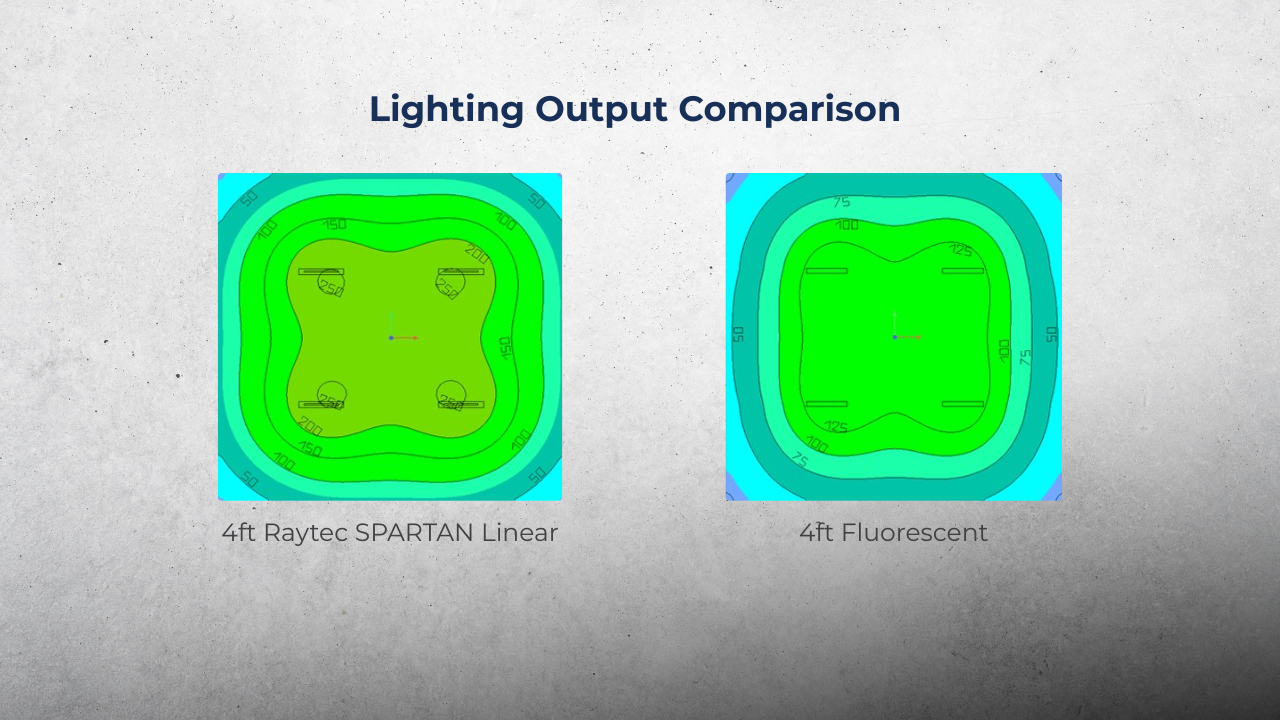

SPARTAN luminaires deliver significantly more output for their size and integrate easily with existing mounting points. Many sites find they can reduce the total number of fittings thanks to SPARTAN’s higher optical performance.

The lighting output comparison clearly shows SPARTAN providing superior light uniformity and intensity versus traditional 4ft fluorescent tubes, enhancing visibility, safety and operational efficiency.

Avoiding Downtime, Risk and Rising Costs

Switching to LED isn’t just about brightness, it’s about eliminating ongoing risk:

- Rising fluoro tube costs

- Shrinking global supply

- Maintenance burdens

- Regulatory compliance issues

- Unpredictable failures

- Mercury handling and disposal obligations

Upgrading to LED ensures your site is future-proof, compliant, safer, and more cost-effective, with dramatically less downtime.

Ready to Make the Switch? We’re Here to Help.

Pacific Automation partners with Raytec to deliver reliable, high-performance industrial LED solutions across Australia. Whether you’re replacing a few ageing fittings or planning a site-wide upgrade, our team can help you:

- Select the right SPARTAN model

- Ensure compliance with upcoming phase-out regulations

- Reduce long-term maintenance costs

- Deliver consistent, high-quality lighting across your site

Contact Pacific Automation today to start your transition away from fluorescent lighting, before the deadlines hit.